Gypsum Type A

The Flexible One

The advantages of our gypsum board cooling and heating ceilings are quickly revealed. We do not supply you with prefabricated registers for the construction project and we do not force you into a fixed assembly corset.

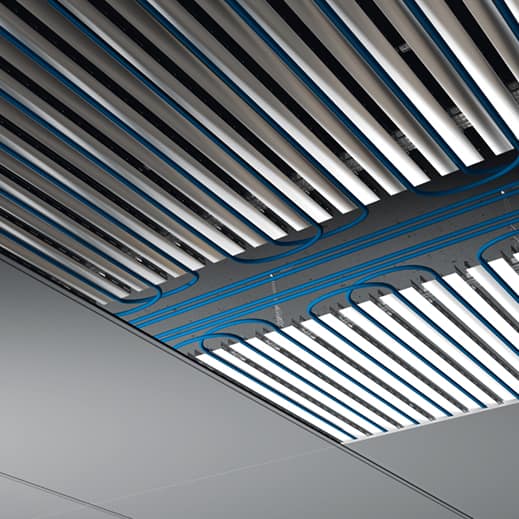

Our solution "from the shelf" is hardly to be surpassed in flexibility any more. Rolled aluminium heat conducting profiles also serve as a construction profile into which the planking is screwed at the end.

Short-term changes in the ceiling plan, such as the relocation of a luminaire or other installation part, can easily be made without having to rethink the entire planning and without producing enormous costs.

The water-carrying pipes consist of diffusion-resistant composite pipes, which are inserted into the profiles on site. The defined transition point to the on-site TGA is our control loop distributor with patented plug-in fittings.

The solution approach with a control loop distributor, in which one ball valve per beam is installed at the factory, replaces the otherwise necessary internal piping and thus ensures that the transfer point to the technical building equipment does not take place in the grey zone of the ceiling cavity, but is clearly and tangible defined.

In addition to water quantities and pressure losses in the zones and circles, our hydraulic designs also show the dimensions of the manifold and the maximum pipe lengths. The fine adjustment of the water quantities is carried out during commissioning on the fixed Taco-Setter of the manifold.